Aluminium Extrusion Engineering

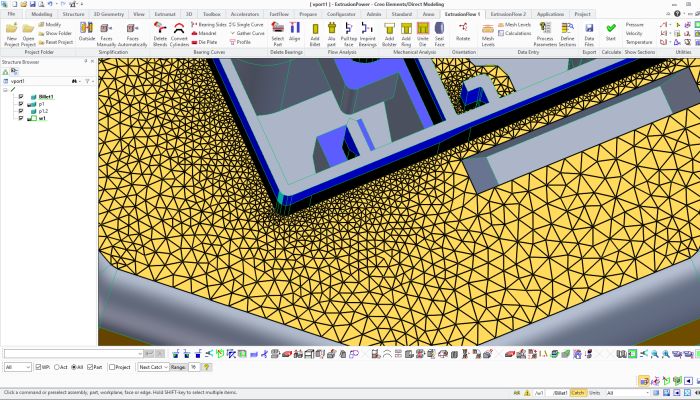

Extrumat

With few clicks Extrumat automatically delivers 3D extrusion die models in a very short time from a 2D extrusion die drawing

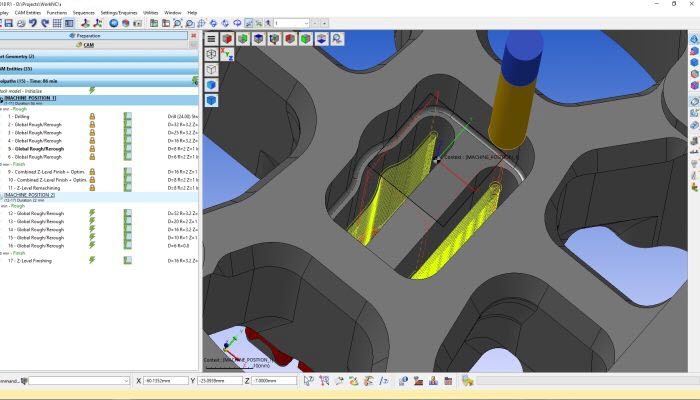

ExtrusionCAM

ExtrusionCAM is the premier automatic CAM software for surface or solid models in aluminium extrusion die industry for 2 to 5-axis CNC programming.

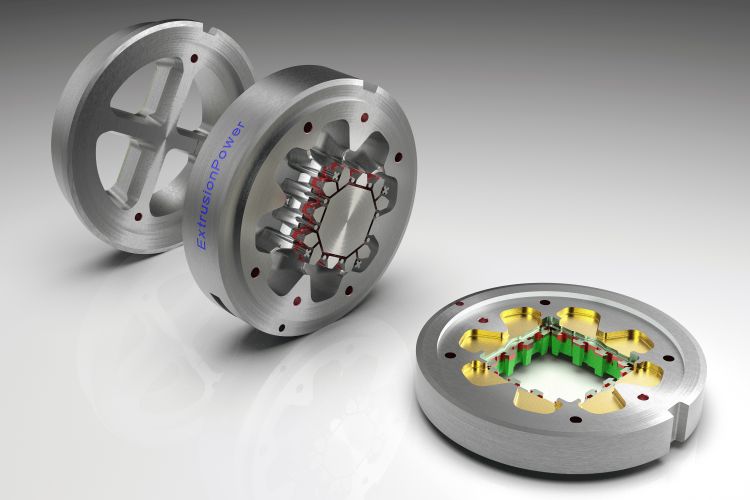

ExtrusionFlow

ExtrusionFlow is an engineering software that enables die designers to analyze metal forming processes on the computer rather than the shop floor using trial and error.

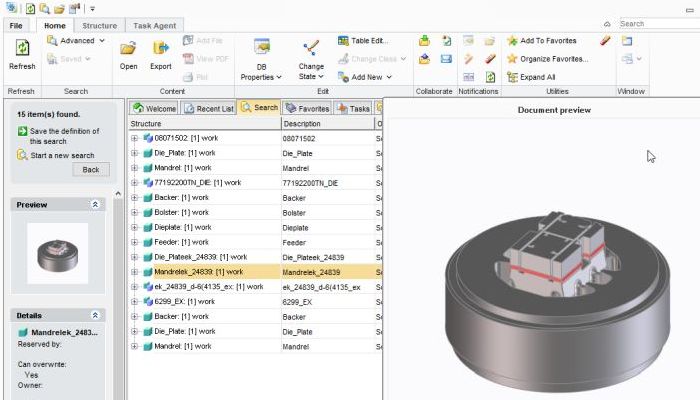

ExtrusionManager

Extrusionmanager is an advanced PDM solution for Aluminium Extrusion Companies that helps you manage the data and streamline the processes.

Our other Competencies

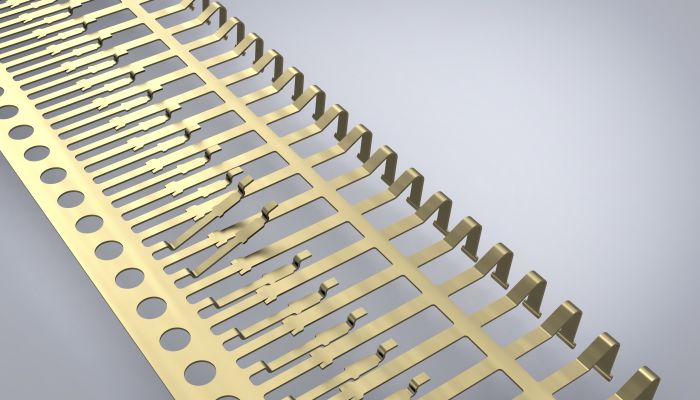

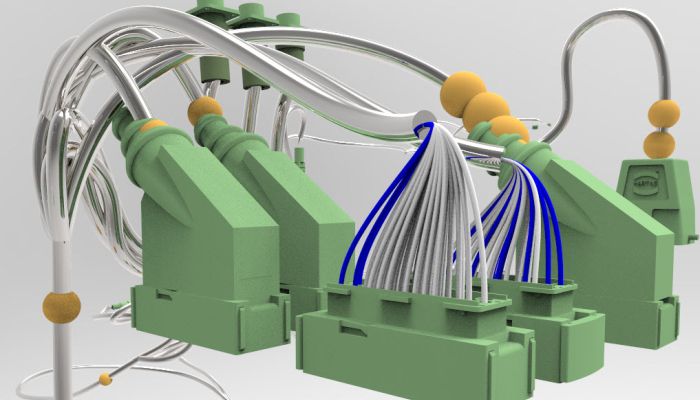

Cabling and Harness Design

3D Cabling and Wire Harness Design allows electrical and mechanical engineers to collaborate to create accurate digital mockups containing both mechanical and electrical components. We offer different software products focused for the production of 3D Cables and Wire Harness.

Facade Engineering

Building façades are considered to be one of the most expensive and potentially the highest risk element of any major building project. Financial success in the facade engineering requires advanced software technologies, with the introduction of Building Information Modelling (BIM).