Cabling and Harness Engineering

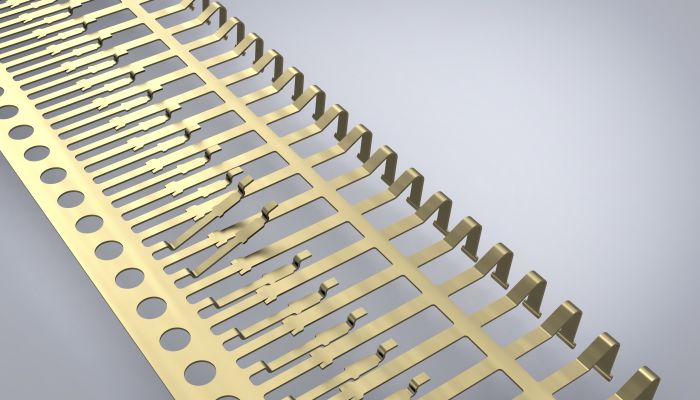

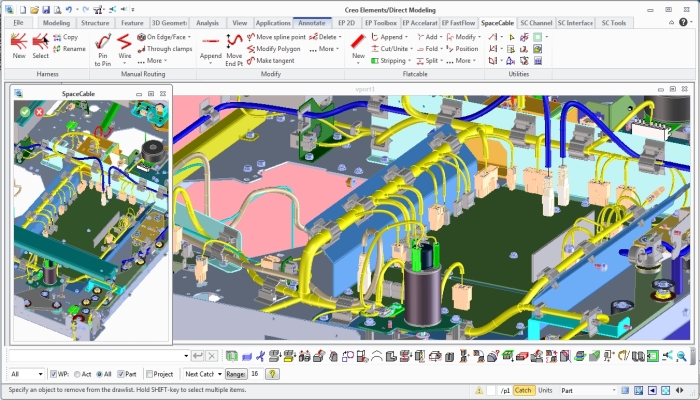

SpaceCable Base

SpaceCable is a 3D CAD Harness solution, which enables mechanical and electrical designers to work concurrently together, enabling accurate 3D digital virtual prototypes and concurrent engineering within the overall electromechanical environment.

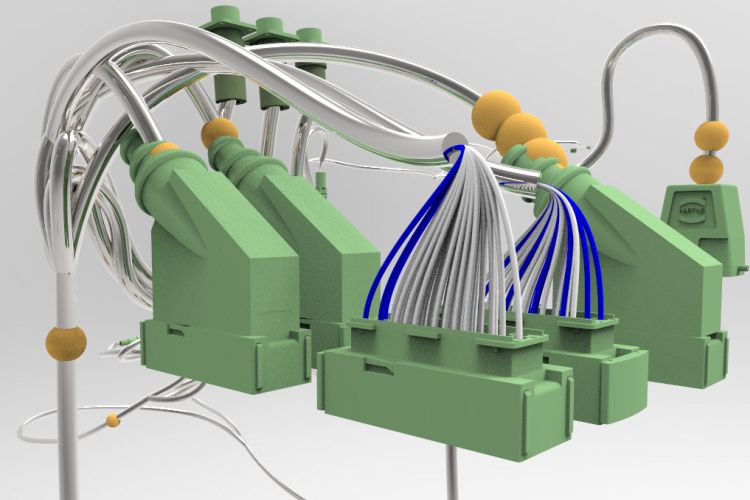

Automotive Accelerator

Automotive Accelerator responds to the ever-growing importance and complexity of vehicle systems associated with electrical and electronical distribution systems and wire harnesses.

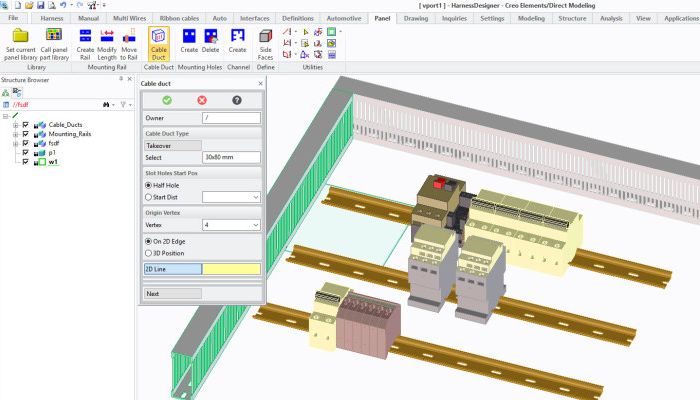

Panel Accelerator

Panel Accelerator provides a design environment enhanced for electrical 3D cabinet design and allows engineers to layout components inside panel enclosures

E3 Link

Bi-directional interface between SpaceCable and Zuken's E3.series software solution, for documenting and detailing electrical design projects.

Our other Competencies

Facade Engineering

Building façades are considered to be one of the most expensive and potentially the highest risk element of any major building project. Financial success in the facade engineering requires advanced software technologies, with the introduction of Building Information Modelling (BIM).