Facade Engineering

Building façades are one of most important elements in the aesthetic and technical performance of a building, for achieving the effective enclosure of buildings.

Façade engineering software must consider aspects such as the 2D drawings, 3D models, fabrication technology and installation of the façades with regards to the performance of materials, aesthetic appearance, structural behaviour, weathertightness, safety and serviceability, security, maintenance and build ability.

Other factors include computational fluid dynamics, heat transfer through two- and three-dimensional constructions, the behaviour of materials, manufacturing methodologies, structural engineering and logistics.

Companies are looking for significant reductions in costs and lead times, thus taking a closer look to all the steps of the production process in order to identify opportunities for reducing cycle times.

For reducing time to market product life-cycle management (PLM) solutions are applied more and more.

In the area of facade design and manufacturing we have the following two solutions

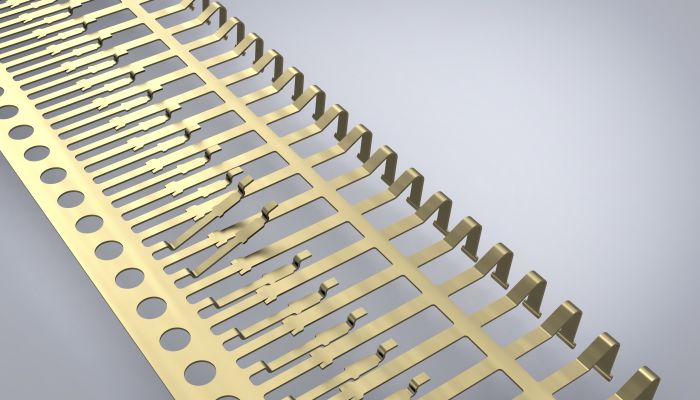

FramesLink

"FramesLink" is a "Creo Elements/Direct" add-on application for the design of frame type structures from steel, aluminum and other materials for the mechanical engineering and construction sector.

PanelCAD

PanelCAD accelerates the design and manufacturing of Building façade systems, from detailed work up to the complete 3D modeling.

Our other Competencies

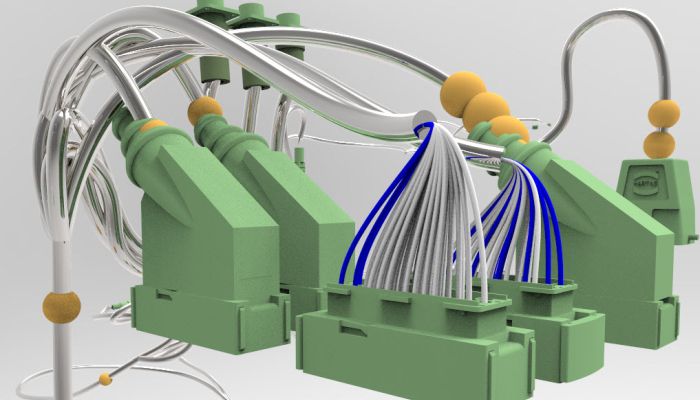

Cabling and Harness Design

3D Cabling and Wire Harness Design allows electrical and mechanical engineers to collaborate to create accurate digital mockups containing both mechanical and electrical components. We offer different software products focused for the production of 3D Cables and Wire Harness.